EV battery assembly production cycle time reduced by 70%

3rd December 2024 | 2 min read

The Challenge

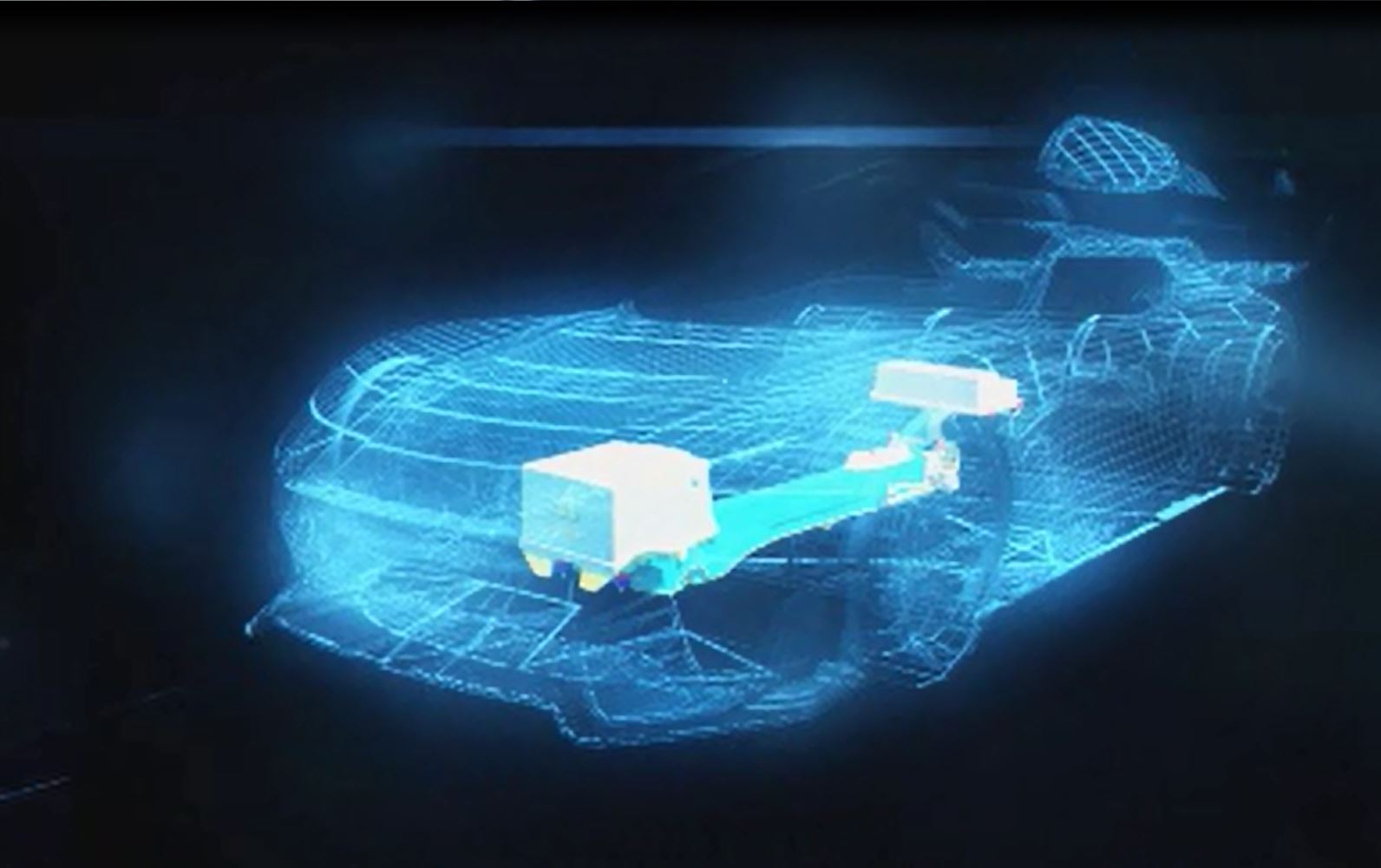

Hyperbat, one of the UK’s leading manufacturers of high-performance EV battery packs and supplier of batteries for the world’s most powerful production car, needed to increase EV battery assembly speed whilst maintaining precision.

Electric vehicles feature multiple battery modules, each comprising approximately 6,000 Li-Ion cells that all require the perfect weld. It is critical that every weld is precise, consistent and safe – any failure can be catastrophic.

Welding electric vehicle battery cells to busbars presents several challenges due to the unique characteristics of Li-ion batteries and the stringent safety and performance requirements in the automotive industry.

Cells and associated busbars need to be clamped accurately to enable precision welding of the busbars to the positive and negative terminals of all individual cells to achieve effective electrical conductivity. This time-consuming process results in long lead times and operational inefficiencies.