Production logistics optimised for UK powertrain manufacturer

17th January 2025 | 2 min read

The Challenge

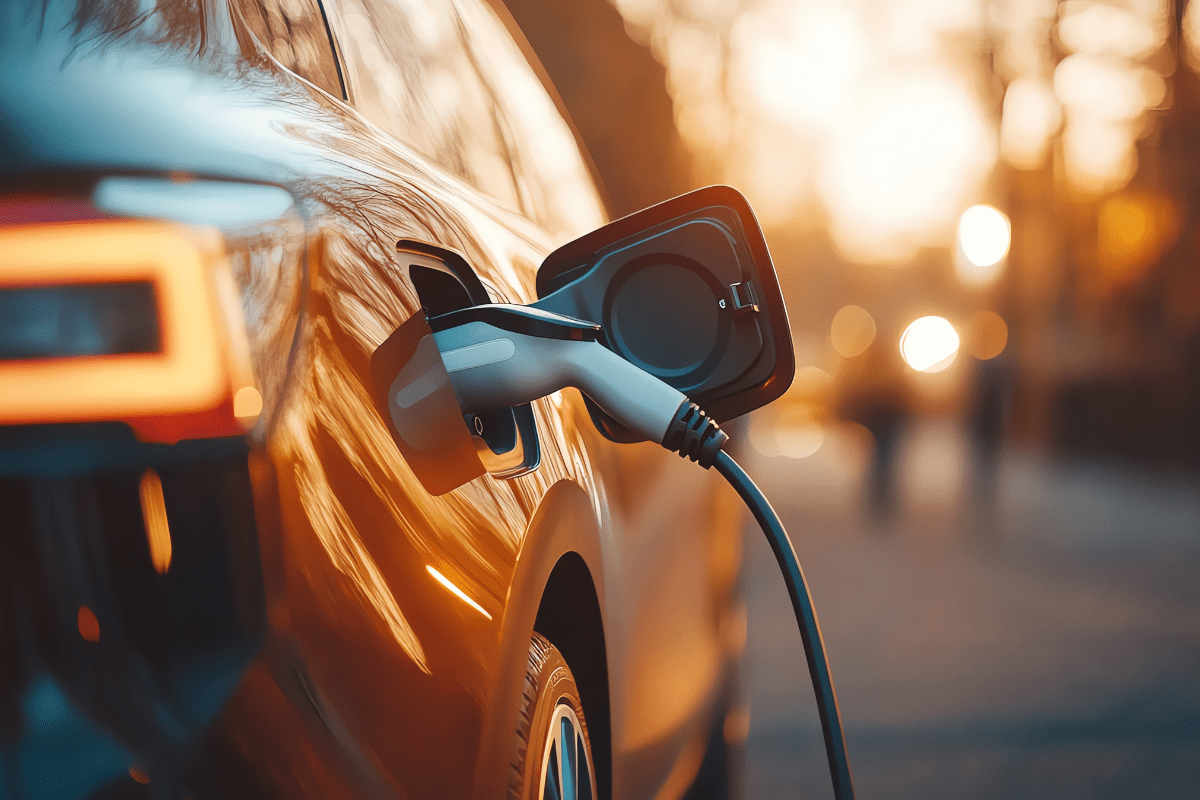

Our customer, a manufacturer for electric powertrains, has the ambition for substantial business growth in the next five years. To support this, the customer is investing £5 million to establish a UK production facility for electric powertrain platforms. This shift will transition them from single-piece custom designs to volume production of eight standardised motor platforms. Designed in-house with specialised machinery, the facility is projected to produce 5,000 units annually.

Unipart Consultancy initially supported the customer with a value stream mapping exercise to inform the facility’s layout, and identified:

- Limited space for material storage

- An inbound supply chain profile that was also heavily skewed by minimum delivered quantities from far-eastern suppliers

- Significant variations in volume across the eight platforms being produced, presenting challenges for unique part storage and production volumes.