Successful delivery the Selhurst REB upgraded manufacture

24th May 2024 | 2 min read

The Challenge

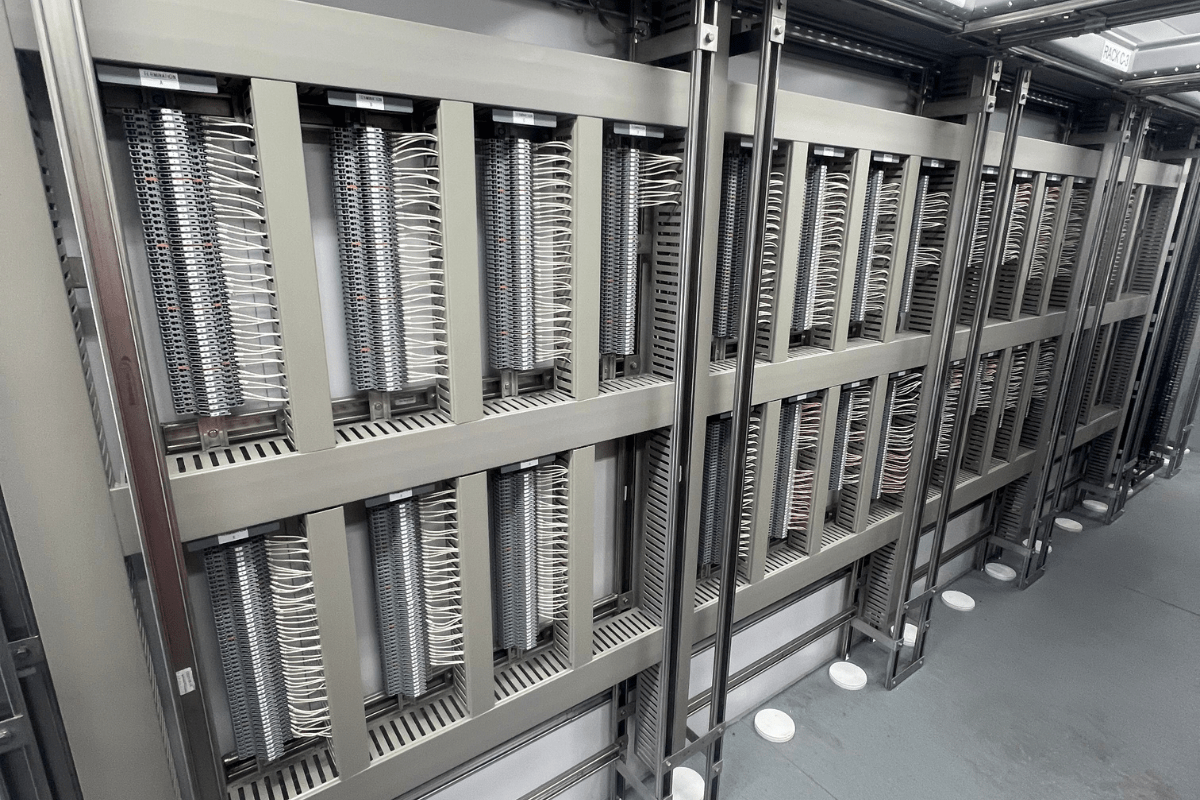

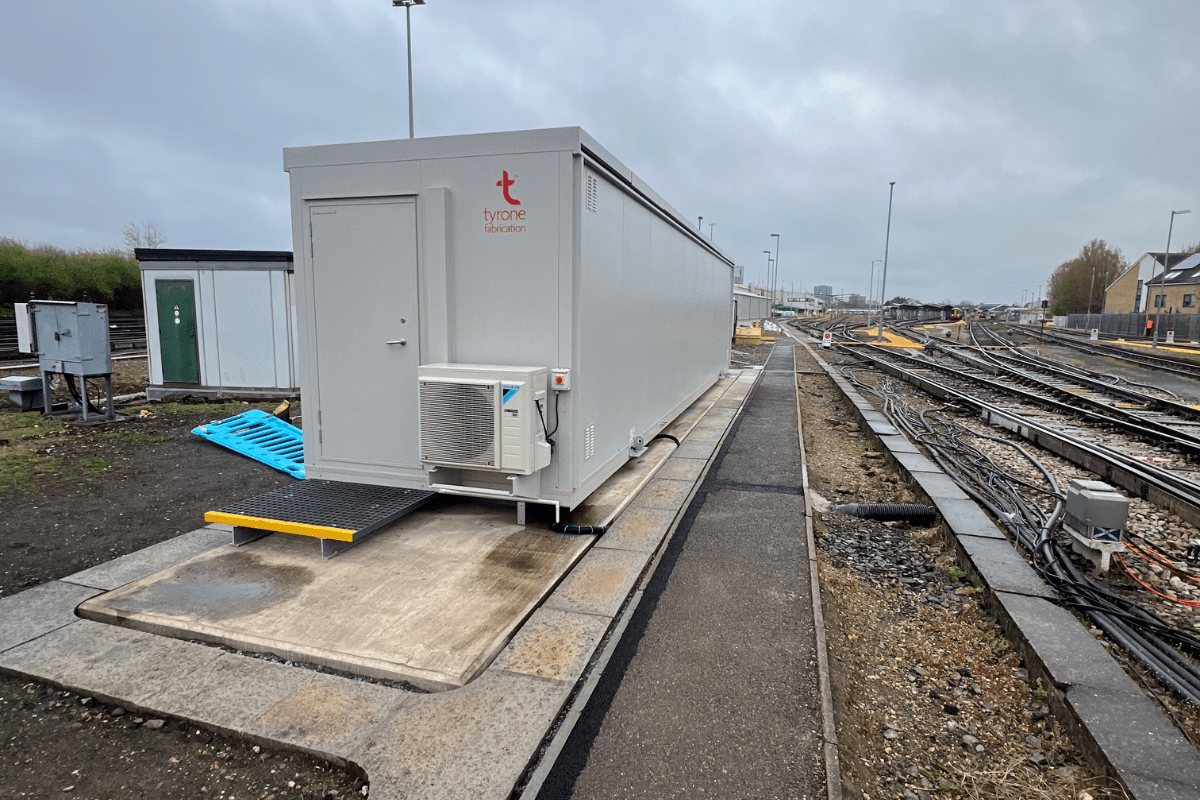

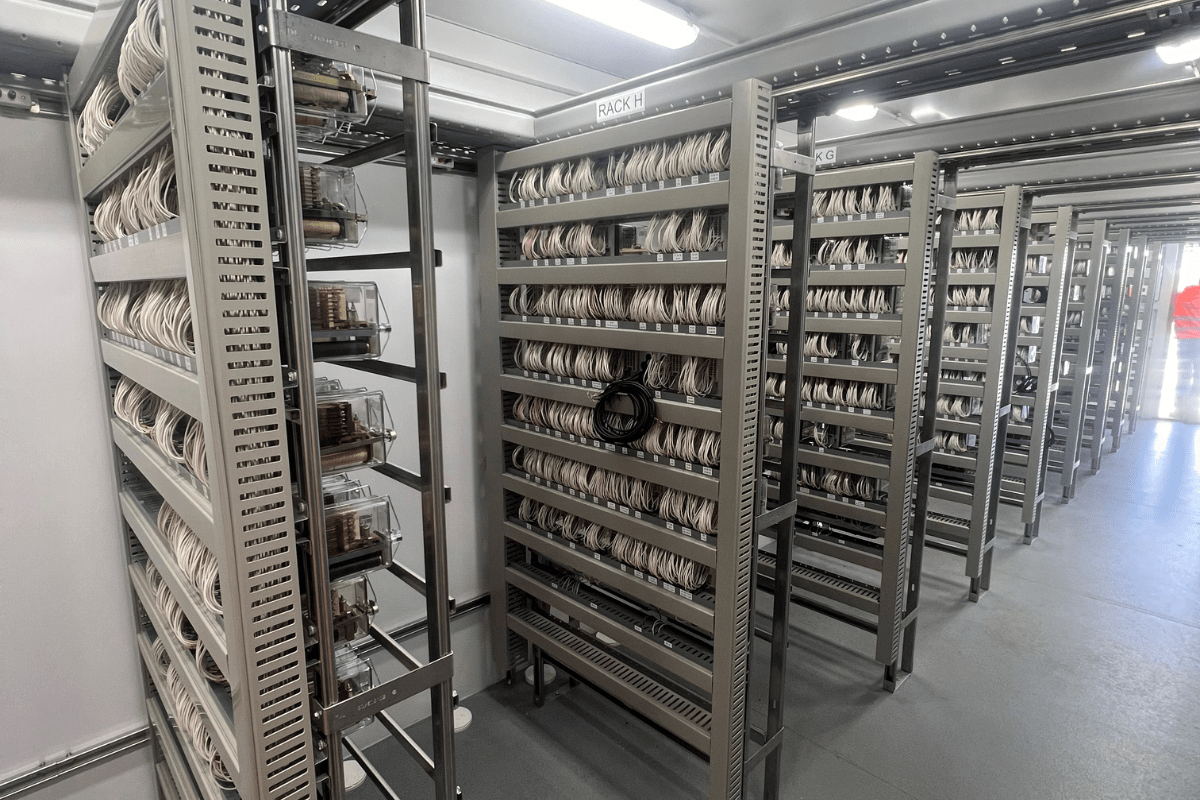

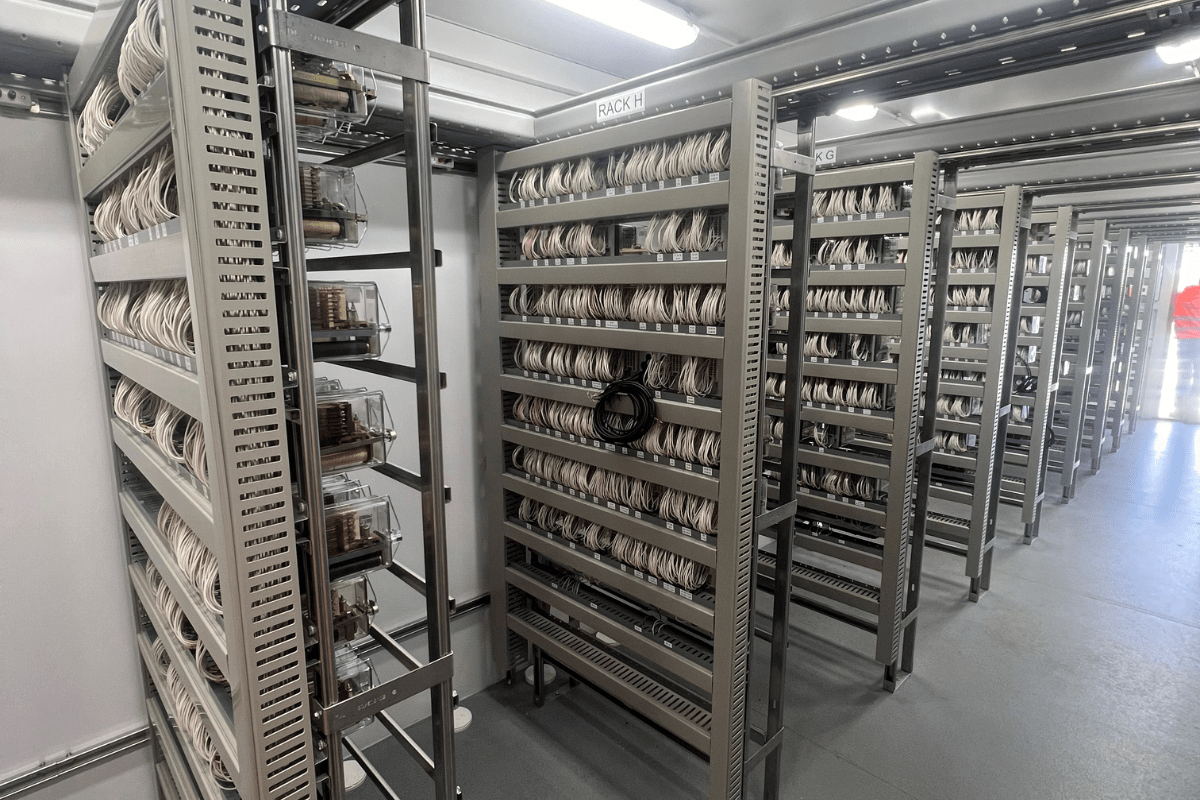

Network Rail Capital Delivery team identified there was severe CAT 4 wire degradation within an REB (Relocatable Equipment Building) at London’s Selhurst Depot.

This was unearthed during their routine maintenance activities and was quickly escalated due to the significant risk of potential signalling failures on the network controlled by the Selhurst REB. The REB at Selhurst hadn’t seen any design specification changes and the only drawings for the design of the REB were the original drawings dating back to 1987.