Leveraging over 40 years of experience, Unipart delivers world-class quality, precision, and reliability in high-volume production for a diverse range of industries.

Our end-to-end production capabilities cover everything from prototype to volume manufacturing, with flexible, scalable solutions to match your production needs. We are committed to uncompromising quality, traceability, and efficiency at every stage.

Unipart’s scalable and flexible solutions ensure consistency, speed, and exceptional results, meeting the demands of today’s fast-paced markets. We are committed to continuous improvement and employ lean thinking and waste elimination to optimise our processes and deliver cost-effective production tailored to your specific needs.

Core manufacturing capability

Scalable, high-quality manufacturing across metals, composites, and polymers—with the flexibility to meet evolving customer and sector needs.

Plastic fuel systems

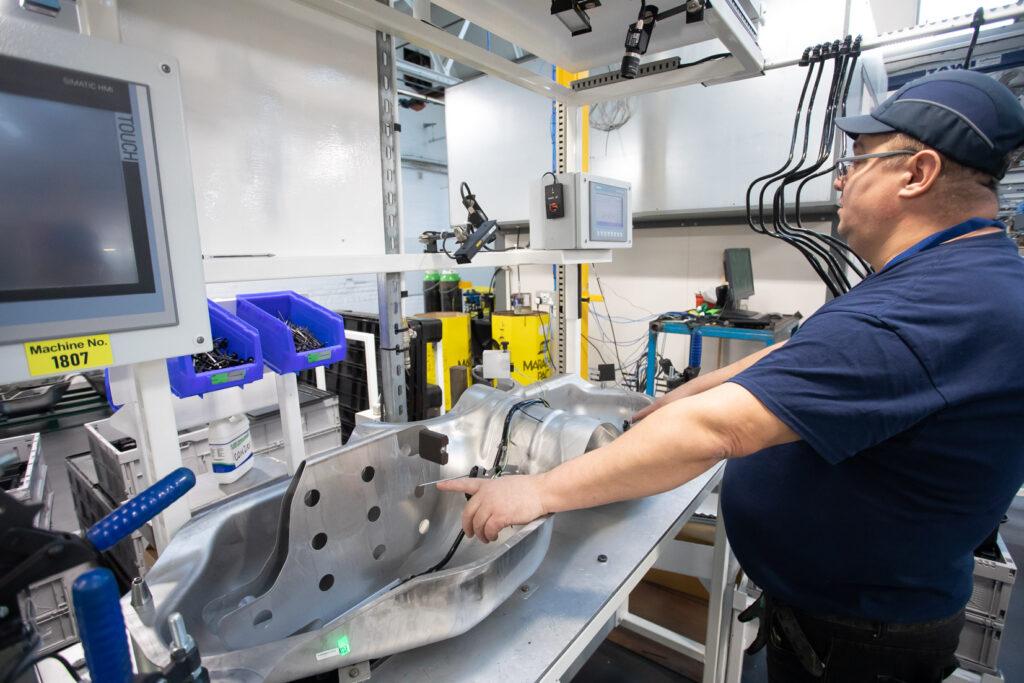

PHEV metal fuel systems

Composite and polymer components

Metal fabrication and welding

Injection moulding

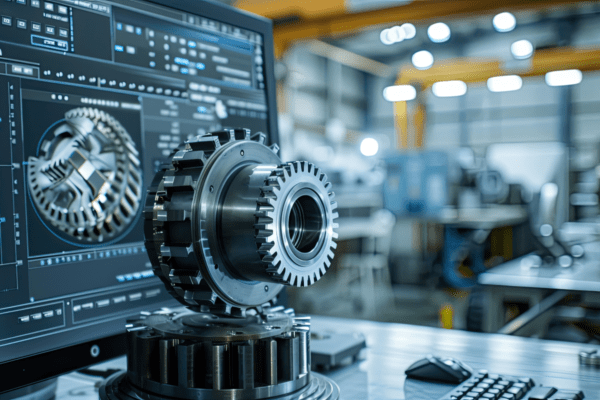

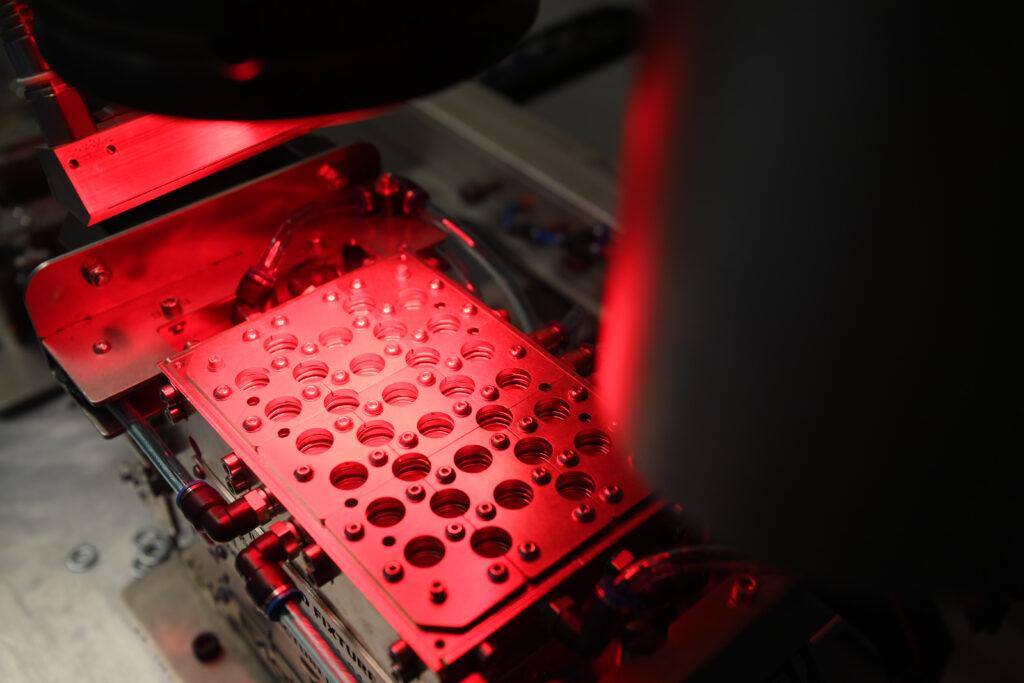

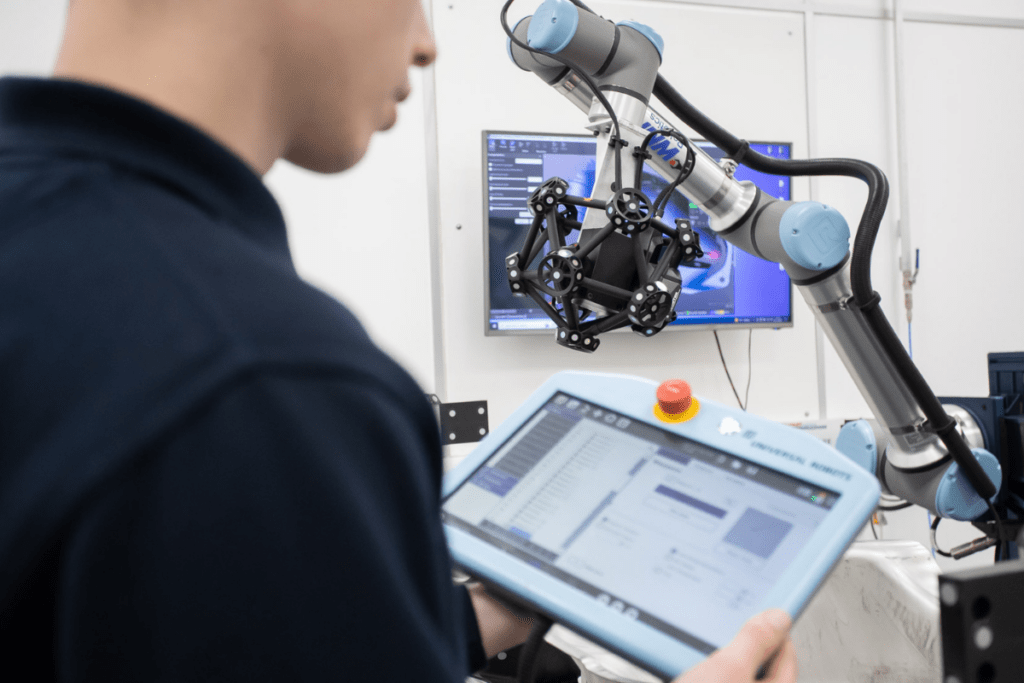

Automation and smart inspection

Automotive-grade fuel systems via KUL joint venture, servicing major OEMs.

Tier 1 supplier of safety-critical fuel systems, including metal tanks, filler pipes, and fuel rails, for automotive OEMs.

Specialist composite production at scale via our composite solutions facility.

High-precision fabrication using multiple welding technologies, including brazing, for complex and large-scale applications.

Tooling and manufacturing for high-specification polymer parts (interiors, housings etc.).

Vision systems, automated testing and digital traceability to deliver zero-defect production across all high-volume lines.